Custom Built Geometry Parlee Z-Zero Bicycle.

Do you want the ultimate bicycle where the bicycle geometry is designed and built specifically for you?

Do you want the carbon on the bike to be selected to suit the way that you ride?

Do you want to choose the paint job or choose to display the raw carbon of your unique bike?

Do you want to choose every aspect of the componentry as well?

A custom built Parlee Z-Zero is the bike for you.

Parlee Z-Zero models are each perfectly designed and built for one person: you.

Creating the ultimate in custom performance is achieved through a combination of bike fitting excellence, engineering technical design, unwavering attention to detail, and total pride in the finished product. Building a bike with Onebody and Parlee is the ultimate in creating the ideal bike for you.

Bike Fit Geometry

Onebody bike fitting can provide you with the geometry of a bicycle that is built around your ideal biomechanics.

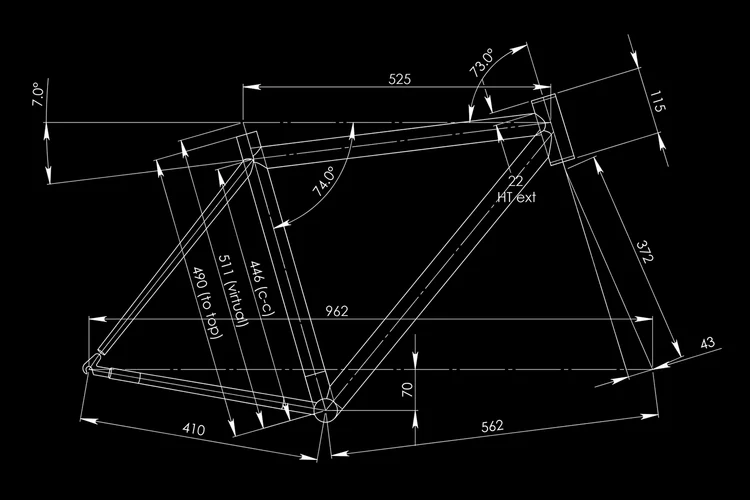

Parlee have the skills and craftsmanship to build that bike to the closest 0.1 deg angularly and 1 milimetre linearly.

Full custom fitted geometry is available on Parlee Z-Zero, Z-Zero Disc, Z-Zero XD (CX, Gravel or Commuter spec) platforms. All custom designs are created using parlee proprietary Computer-Aided-Design system, which models you unique contact points and aligns them with actual frame geometry to assure a flawless finished product.

Ride Feel

Consider the adjectives that describe a bike: quick, stiff, smooth, comfortable, responsive or stable. Each is subjective, resulting from that bike’s tube diameter, tube length, fiber composition, fiber orientation, and angular permutations. Understanding the delicate dance of these variable characteristics is knowledge only attained through years of hands-on observation and practical experience building bicycles.

For over two decades, Parlee has built customized carbon fiber bicycles, for a very broad spectrum of riders, from well-known professionals to enthusiastic amateurs. From these experiences, we have the knowledge, data, and skill to precisely tune each Z-series bicycle to your individual needs. This is a marked departure from standard industry practice, where bikes are designed based on the law of averages. A Z-series, precisely built for you, will be anything but average.

All Z-series tubes are custom blended (at no extra charge) on all made to order Z-series bicycles to perfectly meet each riders needs. The gorgeous carbon tubes and frame parts are all made by hand, in house in Massachuessetts, USA by the Parlee frame building team to Bob parlees exacting designs.

And use carbon variations to tune the ride quality of the bike to be exactly what you wanted.

To finish the bike, you can choose any paint job that you can imagine or choose to display the raw carbon quality of your one of a kind Parlee.

Components

1: Building the Ideal Geometry

It all starts with a Retul Frame Selection Bike Fit where we can determine the ideal bike position for your biomechanics. During this fit session we also determine the frame stack and frame reach geometry that will work well for you. This information is then delivered to Parlee’s state-of-the-art Massachusetts headquarters, where they use custom CAD software to create the blueprint of your perfect bike based around the information that we supply. The details of your ideal bike geometry are shared between you and Onebody to ensure that the ideal frame geometry is being built.

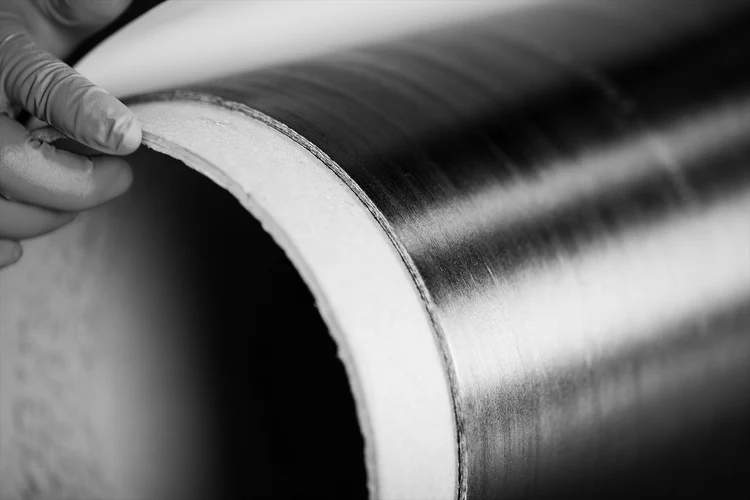

2: Custom Carbon Fiber

Every Parlee frame starts with high-modulus, uni-directional carbon fiber tubing. These tubes and sub-assemblies are produced exclusively by Parlee, and each one is meticulously inspected, then mitered to size. After the ends are cleaned and media-blasted, the tubes are inspected again. The goal is to create the perfect surface to work with, which is critical to long-term durability. This process is one reason that Parlee frames are backed by a lifetime warranty.

3: Construction & Assembly

These custom carbon tubes are then selected and assembled based on a customer’s desired ride qualities. Parlee use specially designed jigs that are accurate to sub-1mm tolerances. Each lug is mated by hand around the mitered tubes, which allows us to customize the stiffness level. Correct fiber orientation is key to frame strength and ride quality.

4: Molding

Frames are put through a proprietary heating and pressurization process that creates an unbreakable bond. This proprietary molding process ensures a consistent surface finish.

5: Raw Finishing

Next, frames are hand-sanded and cleaned before small parts are installed. All of Parlee carbon fittings such as cable stops and front derailleur mounts are made in-house. This helps parlee achieve the lightest, strongest connections between the frame and its components.

6: Paint & Final Prep

When it comes to paint, Parlee customers have unlimited color choices. After each frame is assembled, it goes through an exhaustive wet-sanding process, where progressively finer grit paper is used to produce a mirror-like shine. Once the final paint is applied, the total build time for each frame is about 40 hours, up to four times longer than that of the average custom bike.

7. Timelines

The timeline for building a custom made parlee requires the following steps

- Initial Bike Fit and frame Geometry Planning

- CAD geometry design approval

- Paint Job or Finishing CHoices

- Component Selection

- Parlee Frame Manufacture

- Custom Building in Australia

- Final Bike Fit

The average delivery time for a custom frame is about 30-45 days from approval of the CAD geometry and paintwork / finishing. Custom building in Australia and final bike fitting takes about 14 days. The total time from start to finish is general about 6-8 weeks